Inventory Management

Master Inventory Management on the Go with ServeDeck

ServeDeck’s inventory management system provider solution empowers facility and property managers to automate inventory tracking, reduce stock discrepancies, and maintain real-time asset visibility. Featuring barcode scanning, low‑stock alerts, and audit trails, our system ensures grease on-the-ground accuracy while optimizing procurement costs.

With a centralized dashboard and historical usage analytics, ServeDeck helps you streamline ordering, prevent stockouts, and manage consumables efficiently—all within one integrated platform.

Servedeck

Inventory Management features

- All Your Stock, One Platform

- Centralise your inventory record into a single, organized, and easily searchable database.

- Real-Time Stock Levels

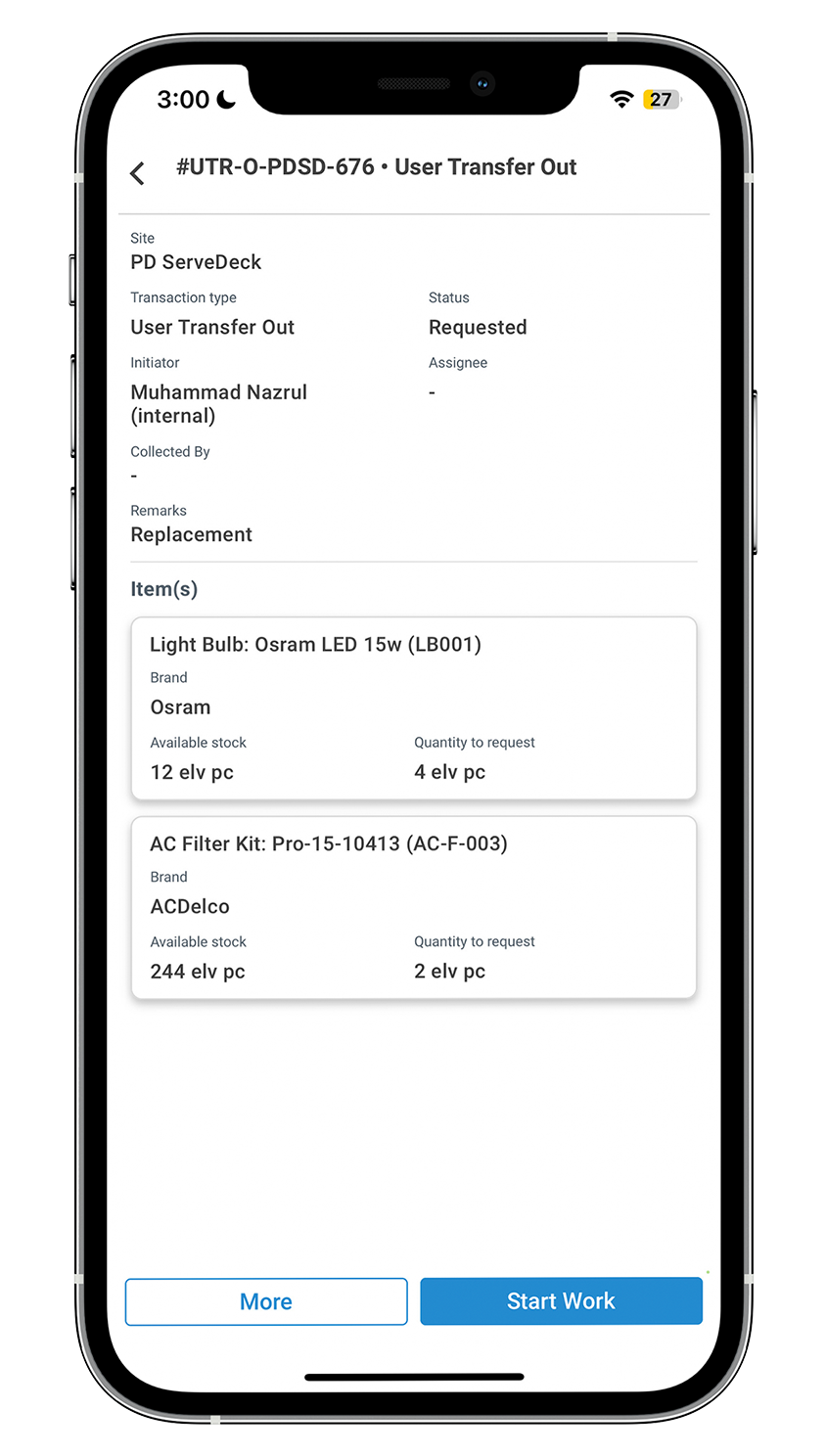

- Management and maintenance staff able to see the quantity of inventory from web and mobile app. Easily plan restock and maintenance activity based on the inventory availability.

- Notifications on low inventory level

- Get alerted on low inventory quantity. Configurable reorder points for each inventory item minimise the risk of stockout.

- Audit-Ready in a Click

- ServeDeck's inventory cut-off feature lets you halt all online transactions to support physical stock take activity. With a single click, ensure accurate stock summaries for any given period. Generate Stock Summary Reports with confidence, knowing your data is always locked in and ready for review.

- Click, Quote, Stock: Purchasing Module

- The Inventory Module and Purchasing Module connect seamlessly, with auto-creation of Purchase Requisition when the quantity reaches reorder point. Track and monitor reorder process until goods received to optimise the lead time.

Benefits of ServeDeck

Inventory Management

Eliminate stockouts and overstocking

Real-time visibility of stock quantity as well historical data on usage and purchasing process will help to optimise inventory management.

Work Order Harmony

Seamlessly track inventory usage within work orders. Maintenance team able to request and add inventory item to Work Order while executing tasks. Immediate updates on stock utilisation allow for precise update.

Boosted Operational Efficiency

Automate tasks like work order linking, reorder points , freeing your team for strategic initiatives.

Cost Control & Waste Reduction

Minimize overstocking and eliminate waste with precise inventory tracking. Make informed purchasing decisions, optimize your budget, and see your profits rise.

Reduced risk

Proactive inventory management minimizes the risk of stockouts, delays in Work Order completion, and unforeseen expenses. Act with assurance and tranquilly of mind.